At DESFA, we recognize that our success is inherently tied to our ability to prioritize the Health & Safety, Security, Environment, and Quality (HSSEQ) aspects of our operations. Our commitment to Zero Accidents is a fundamental value that guides our decisions, actions, and relationships.

Based on the company’s Policies and in accordance with its Code of Conduct, DESFA considers human health, safety, environmental protection, public safety and quality of services as priority objectives for sustainable development.

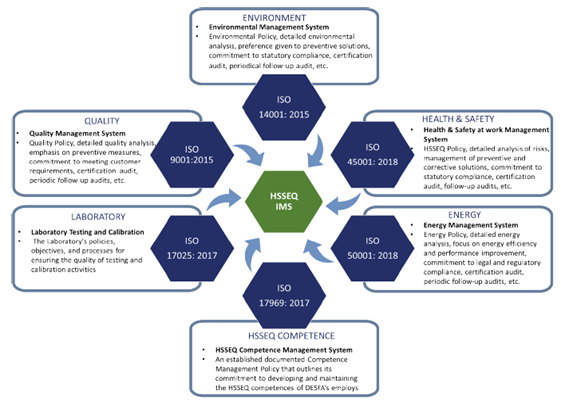

The company is committed to achieving these objectives through the adoption, certification, and continuous improvement of an Integrated Health & Safety, Security, Environment and Quality Management System (HSSEQ IMS).

More specifically DESFA has been certified with:

• ISO 9001 for Quality Management

• ISO 14001 for Environmental Management

• ISO 45001 for Health & Safety Management

• ISO 50001 for Energy Management

• ISO 17969 for the Competency Management System

• ISO 14064 for GHG Emissions Accounting

• Accredited according to ISO 17025 for the operation of its laboratories.

At DESFA, the health and safety of our employees and contractors are our paramount concerns. It is our goal to create a work environment where everyone feels valued, respected, and protected. Our senior leadership is dedicated to the creation of a sustainable organization that delivers significant value for all our stakeholders. We achieve this through the promotion of responsible environmental management, improved energy efficiency, operational efficiency, a high level of health and well-being for employees, and the creation of a safe workplace. In line with these principles, DESFA aims to foster trust, meet customer requirements, and develop long-term relationships based on shared values. To this end, we empower our leadership, employees, contractors, and partners to actively contribute to the advancement of Health & Safety objectives, embracing the value of Leadership by Example.

Environmental stewardship is a core tenet of our business philosophy. We recognize the finite nature of our natural resources and the urgent need to mitigate our impact on the planet. Therefore, we embrace sustainable practices, minimize waste generation, ensure water quality, actively seek opportunities to innovate for a greener future, and reduce emissions with the aim of achieving Carbon Neutrality. Recently, the need for solid energy management, optimization of energy consumption and efficiency have become of paramount importance in the rapidly changing energy market. In response to these needs, DESFA has developed and certified an Energy Management System in accordance with ISO 50001.

At DESFA, we integrate leading and lagging practices to create a holistic HSSEQ framework that prioritizes prevention while also effectively managing incidents when they do occur. This not only safeguards the well-being of employees and stakeholders but also enhances operational efficiency and protects the environment.

Leading practices involve proactive measures that aim to prevent incidents before they occur. These include:

- robust risk assessments,

- continuous training programs,

- regular HSSEQ audits and visits,

- HSE measurements

- Emergency response exercises

Above all, fostering a culture where every individual feels empowered to identify and address hazards is of paramount importance.

In contrast, lagging practices involve reactive measures that respond to incidents after they have occurred. This includes incident investigation, root-cause-analysis protocols, corrective action plans, and performance monitoring to identify trends and areas for improvement.

At its core, process safety is about identifying, assessing, and mitigating risks associated with chemical processes, equipment failures, human error and external factors that could lead to catastrophic events such as fires, explosions, or toxic releases.

To effectively manage process safety in liaison with HSE, DESFA implement’s several practices, including:

- Risk Identification and Assessment: Conducting thorough risk assessments, including HAZOP and HAZID analysis, to identify potential hazards and vulnerabilities in operations.

- Training and Competency: Providing comprehensive training programs to ensure that employees understand the hazards associated with their work and are equipped with the knowledge and skills to operate safely.

- Management of Change: Establishing rigorous processes for managing changes to equipment, procedures, or personnel that could impact process safety.

- Emergency Preparedness and Response: Developing robust emergency response plans and conducting regular drills and exercises to ensure readiness in the event of a process-related incident.

By integrating process safety principles, DESFA can reduce the probability of catastrophic incidents, safeguard personnel and assets, and fulfill its commitment to environmental stewardship and community safety. Effective collaboration between process safety and HSE teams is crucial to achieving these objectives and fostering a culture of safety and sustainability throughout the organization.

DESFA has a long-standing commitment to excellence in Health & Safety, Security, Environment, Energy Management and Quality. This commitment has led to the adoption of a culture of ongoing enhancement and continuous improvement, which revolves around the following:

Regular assessmentsallow us to identify strengths, weaknesses, and areas for improvement. These can include safety audits, environmental impact assessments, and quality management reviews.

It is of the utmost importance to have effective Feedback Mechanisms in place to ensure that HSSEQ practices are continuously monitored and evaluated. This allows for the identification of potential hazards, process inefficiencies and opportunities for enhancement.

Training and Competence: We place a strong emphasis on training and competence development in HSSEQ. This enables us to cultivate a highly skilled and knowledgeable workforce that can navigate challenges, drive innovation, and uphold the highest standards of safety, security, environmental stewardship, and quality.

Data Analysis and Performance Metrics: We utilize data analytics and performance metrics to track progress and identify trends over time, allowing us to address areas of concern with targeted interventions.

Collaboration: Encouraging collaboration allows us to adopt a holistic approach to HSSEQ improvement. By involving stakeholders from various areas, we can leverage diverse expertise and perspectives to drive meaningful change. Management Commitment and Leadership: Strong leadership commitment is essential for fostering a culture of continuous improvement. When leadership prioritizes safety, security, environmental stewardship, and quality, it sets the tone for the entire organization and reinforces the importance of ongoing enhancement.

DESFA has demonstrated its dedication to the Care to Protect initiative, which focuses on safeguarding human well-being and the environment. It upholds this commitment through the implementation of Life-Saving Rules, which serve as the foundation for all its operations. Additionally, it has initiated a campaign for both its employees and stakeholders, Partners4HSEexellence, aimed at sharing its vision.

Physical Security is an integral part of DESFA’s strategy, as it is a prerequisite for the safe and effective operation of the company, and the uninterrupted operation of the National Natural Gas System. To this end, DESFA implements appropriate measures and has the necessary financial resources to create a modern technological ecosystem that is handled by selected and properly trained security personnel, addressing any estimated risks.

In the context of technological modernization, the Physical Security Control Center (KEFAS) operates as an Electronic Surveillance Center, an Information Management Center, a Crisis Response Center and finally a Training Center.

Furthermore, DESFA has installed modern electronic surveillance systems in its facilities to enhance security.

At the same time, cultivates a corporate security culture, as it is a force multiplier, to increase resilience and reduce the vulnerability of facilities to security threats.

We have developed actions aimed at harmonizing with the specifications referred to in the European Directive on critical entities (EU Directive CER 2022/2557). Finally, to evaluate its operational planning on physical security issues in a holistic way, DESFA implements realistic exercises and participates in scale exercises with corresponding infrastructure, specialized bodies, and organizations, with the participation of state authorities such as the security forces and the armed forces.